Built for progression

Revi started because helmets hadn’t kept up - the same compromises season after season. Comfort was overlooked, and “good enough” became the standard. Revi changes that. We built a helmet designed around how riders actually move, think, and push limits. You’ve evolved - riding harder, faster, and with more intention than ever. Your helmet should evolve with you..

At the core of every Revi helmet is ESA® Protection, an integrated impact-management system engineered to absorb and disperse energy across its structure. But protection alone wasn’t enough. We refused to compromise on fit, feel, or the small details that make you actually want to wear it.

From our precision fit system to removable, audio-compatible ear pads and moisture-wicking liners, every element is designed for riders who push limits.

ESA® Shock-Absorption System

Traditional helmets rely on a single layer of EPS foam - it compresses once, then stops absorbing energy. Real crashes aren’t that simple. ESA® is an engineered system co-molded into the helmet’s core, designed to manage impact energy. It responds dynamically - soft at low forces, firm when energy spikes - absorbing and dispersing impact across its structure for consistent protection from small knocks to big hits.

How ESA® Reacts Under Force

ESA® is an engineered layer that manages impact energy through progressive, non-linear deformation. Under force, it compresses softly at low loads and stiffens as energy increases - absorbing and dispersing impact across its structure. Unlike traditional EPS foam, which crushes once and stays deformed, ESA® recovers after impact to maintain consistent performance.

how it's different

ESA® isn’t an add-on - it’s built into the helmet’s core architecture. Integrated with the hybrid shell and precision fit system, it works as one to manage energy more intelligently, reduce peak forces, and do it all without extra bulk or weight.

Hybrid Shell Engineering

Revi’s hybrid shell combines two materials, each chosen for performance:

ABS Outer Shell: Tough and rigid to resist penetration and spread impact forces across a wider area.

In-Mold Polycarbonate Base: Lightweight and fused directly to the liner for added strength and reduced overall weight.

Together, they form a lighter, stronger structure that delivers efficient energy absorption and all-day durability without compromise.

Precision Fit System

A helmet can’t protect what it doesn’t fit. Revi’s precision fit system wraps evenly around your head for a locked-in feel and all-day comfort. Every element works together to eliminate distractions and keep your focus on the ride.

Micro-Adjust Dial: Fine-tunes fit in every direction to remove pressure points and unwanted movement.

Ergonomic Design: Distributes tension evenly for a stable, balanced feel - even on impact.

Removable Ear Pads & Moisture-Wicking Liner: Choose warmth or sound while staying dry and comfortable.

Integrated Goggle Interface: Seamlessly pairs with Revi goggle system for a precise seal, anti-fog airflow, and a unified fit.

No sliding. No pressure points.

Certified Performance

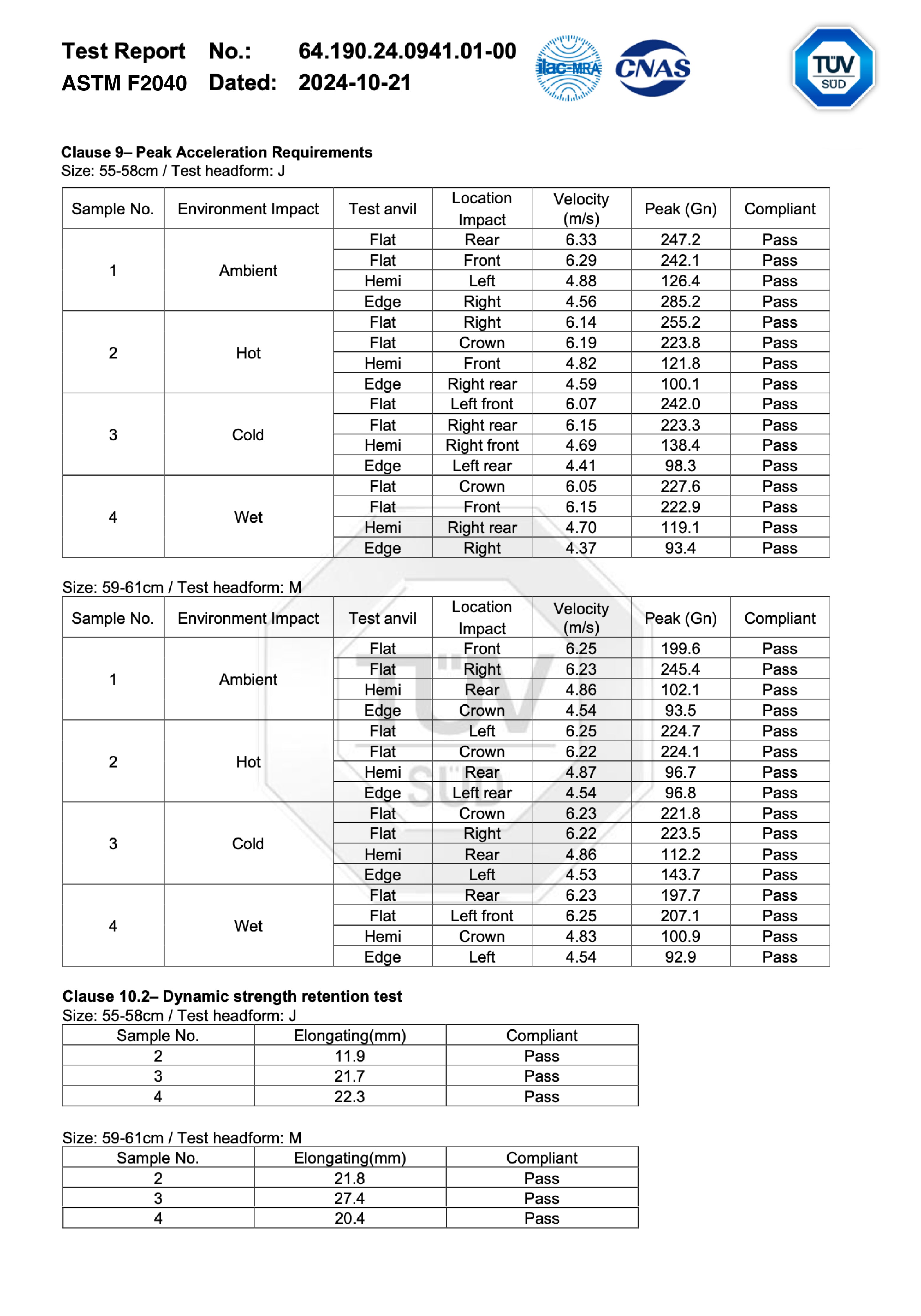

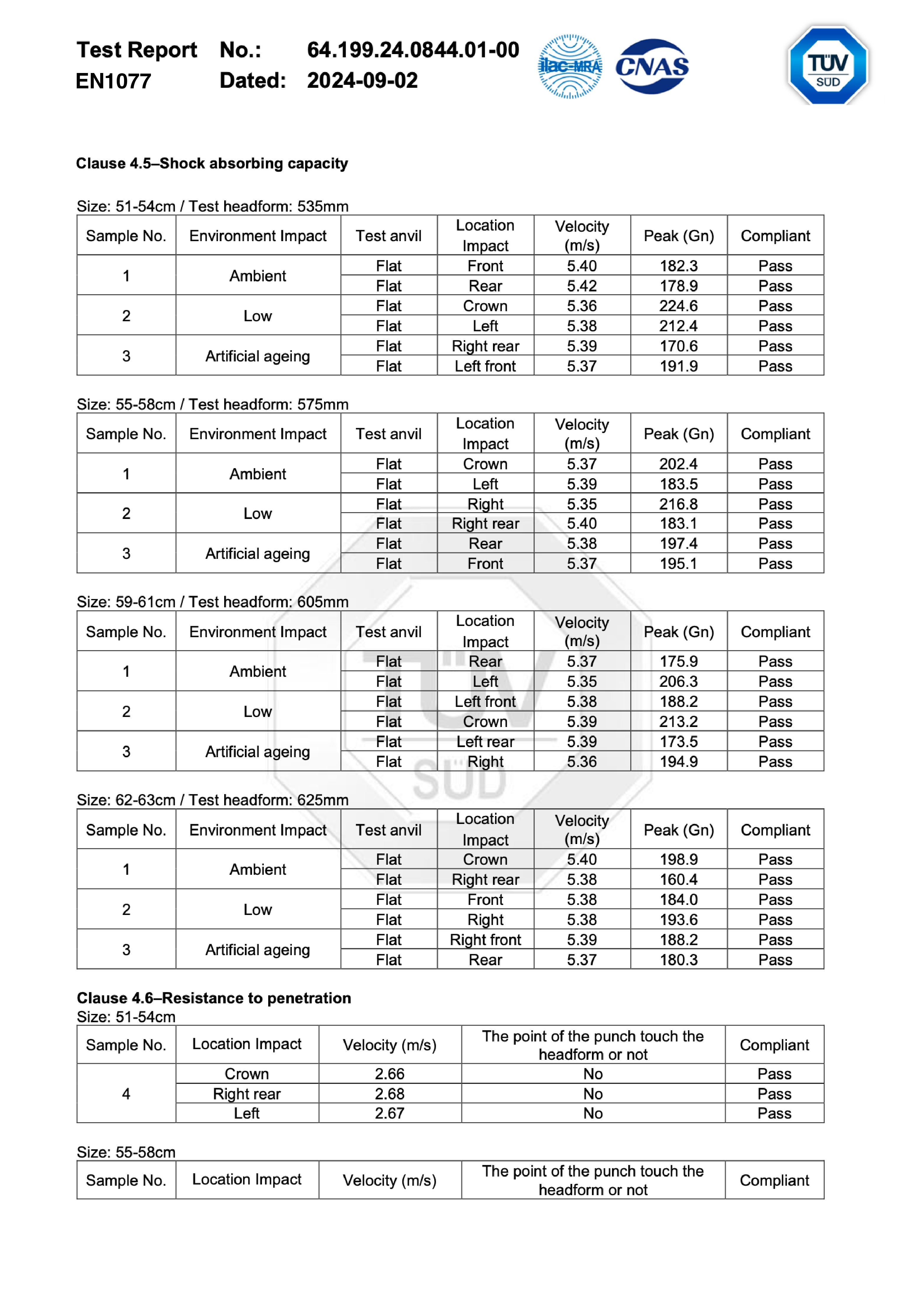

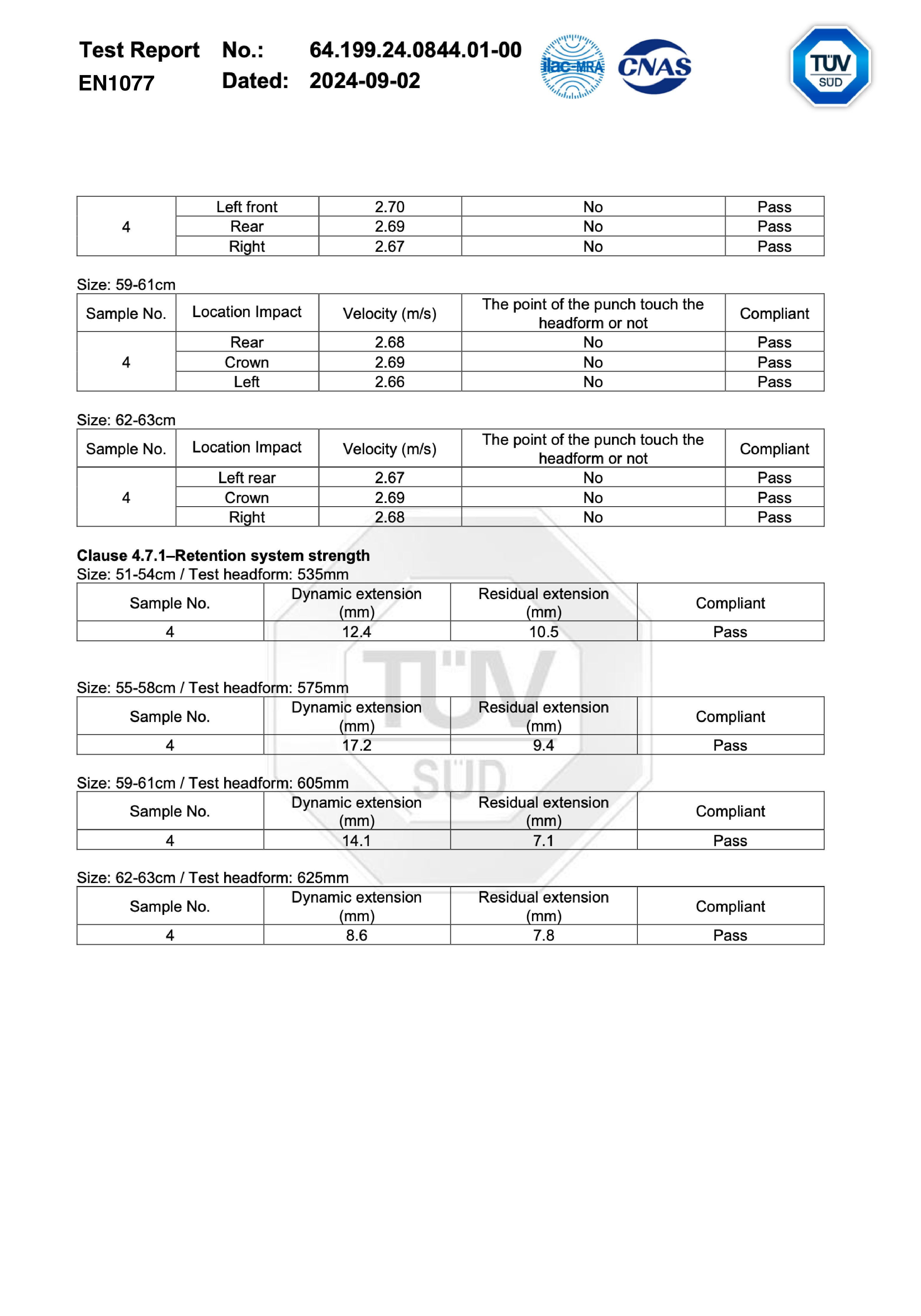

Every Revi helmet is certified to meet the world’s most rigorous snow-sports safety standards: ASTM F2040 (North America) and EN 1077:2020 Class B (Europe). These standards validate performance across key metrics - impact energy absorption, retention system strength, penetration resistance, and field-of-vision safety.

All testing is conducted by accredited third-party laboratories under controlled conditions, verifying that every helmet meets strict performance and cold-weather durability requirements.

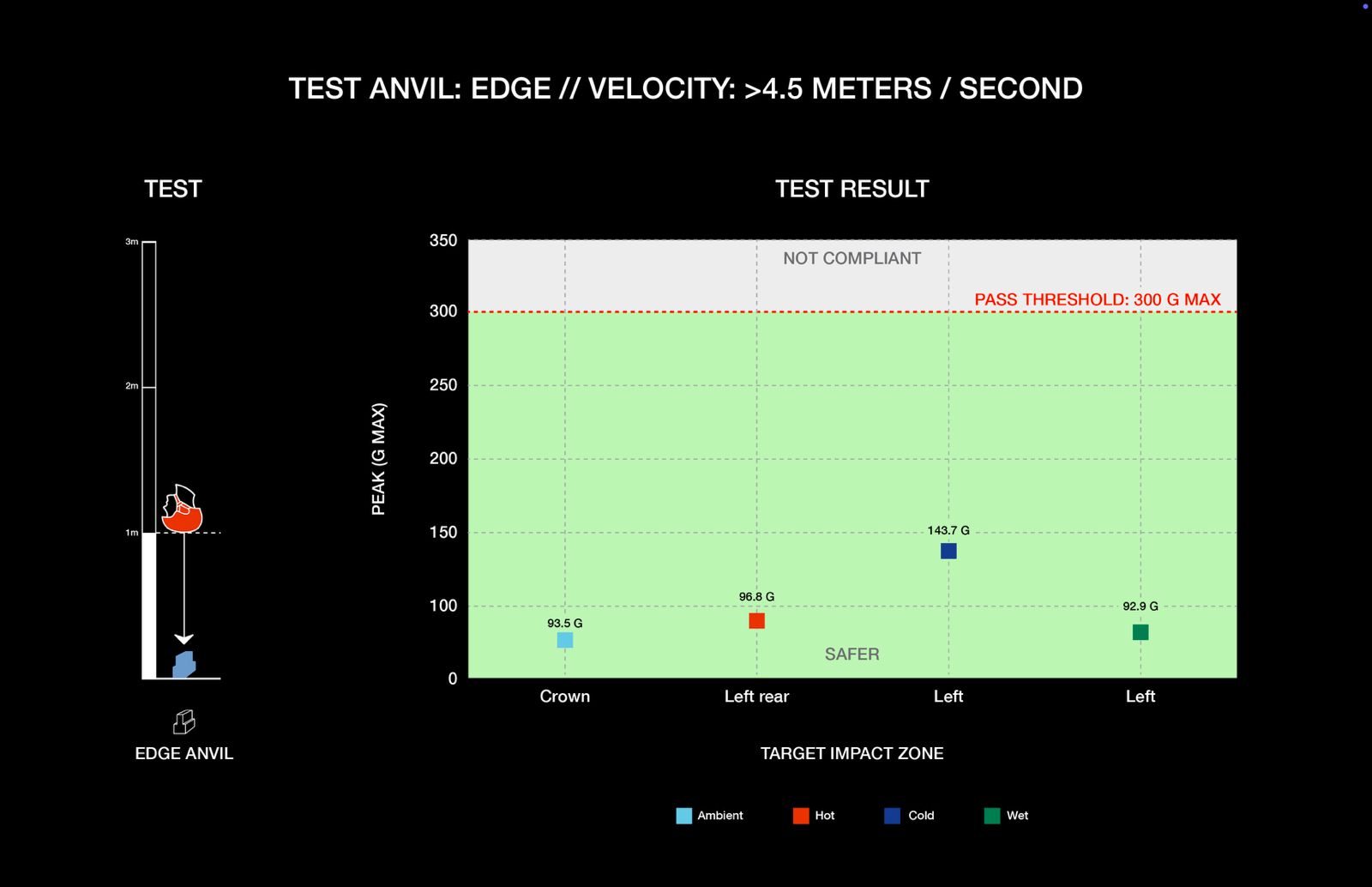

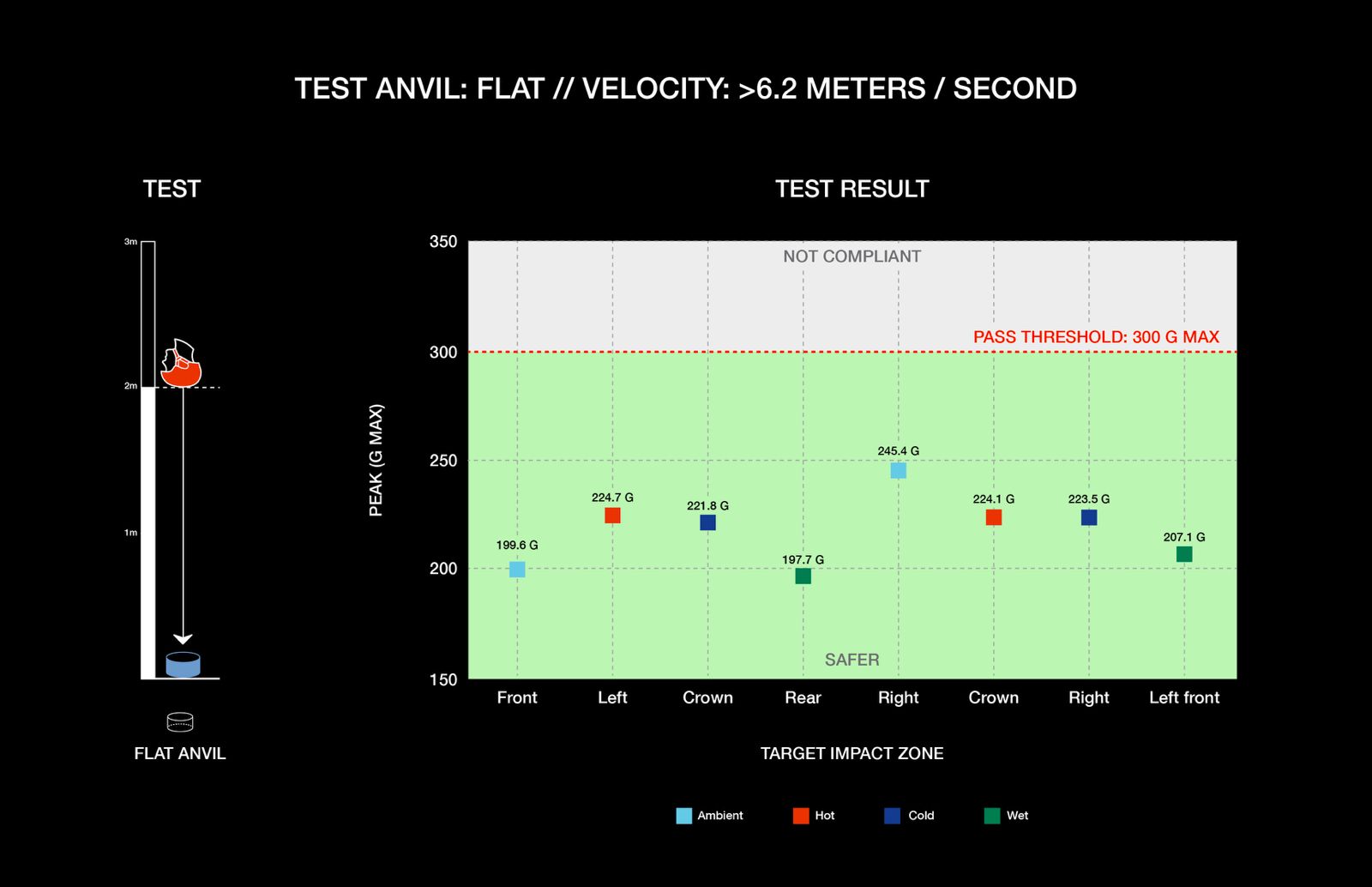

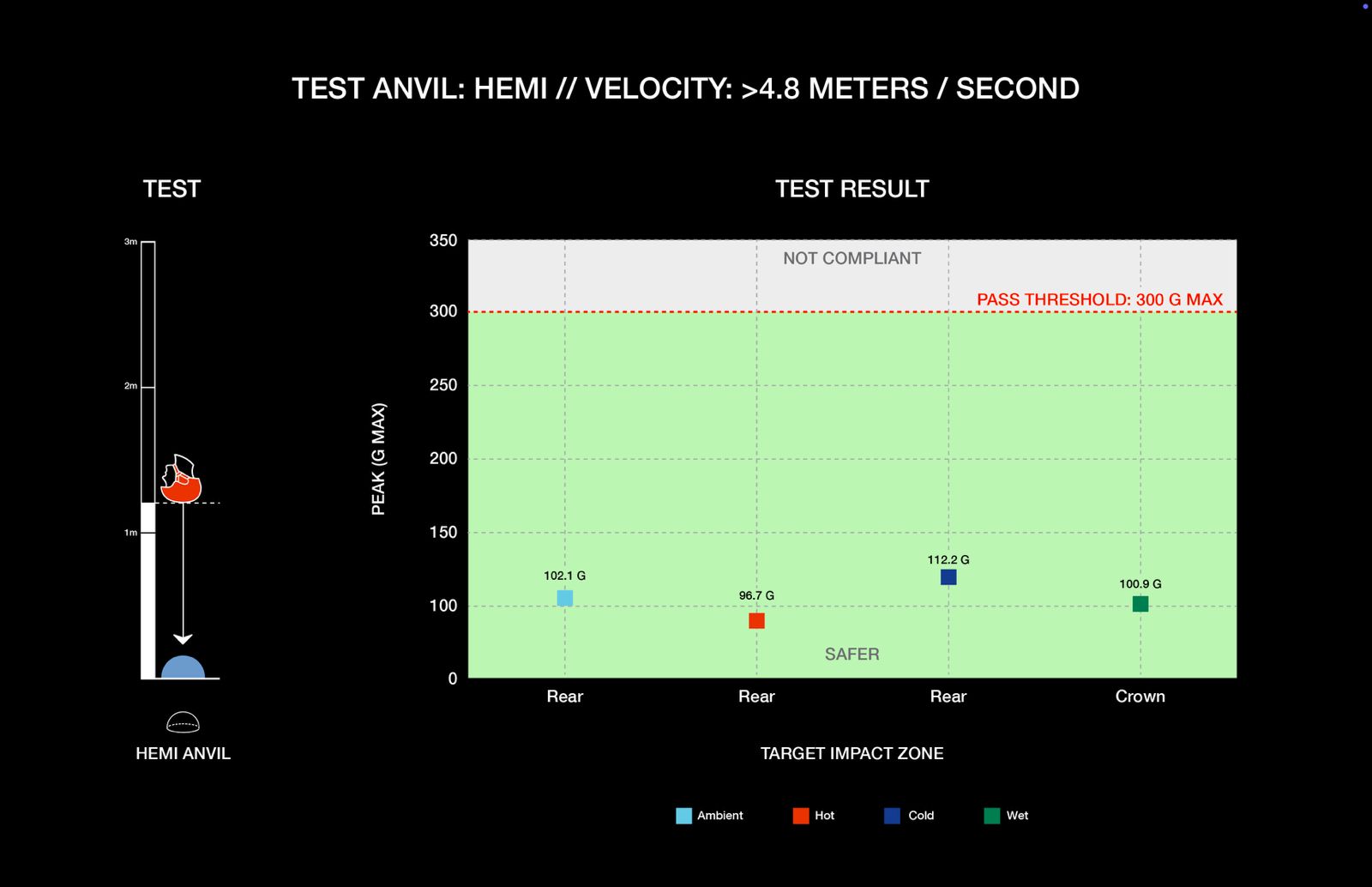

Helmets are dropped onto steel anvils at controlled velocities to measure how effectively they attenuate impact energy. Sensors inside a test headform record peak linear acceleration (measured in g forces), verifying that the helmet keeps impact forces below the maximum limits specified by safety standards.

A pointed striker is dropped onto the helmet shell to test its ability to resist sharp-object intrusion — simulating contact with rocks, ice, or equipment edges.

The chinstrap and buckle system are loaded with force to verify they remain secure under tension. This ensures the helmet stays in place during a fall or sudden impact.

Measurements confirm the helmet’s shape and visor openings provide a wide, unobstructed field of view, ensuring awareness on the mountain.

IMPACT ATTENUATION

PENETRATION RESISTANCE

RETENTION SYSTEM STENGTH

ASTM F2040 Peak Acceleration Requirements Test Results

ASTM F2040 + EN1077 CERTIFICATION

ASTM F2040 [01.]

Measures peak acceleration and retention strength under dynamic load to verify impact attenuation and helmet stability.

EN1077:2020 [01.]

Measures impact attenuation and shell integrity by testing peak acceleration and resistance to sharp-object penetration.

EN1077:2020 [02.]

Evaluates dynamic load and strap elongation to confirm buckle durability, chinstrap stability, and reliable helmet retention.

What It Means for Riders

ASTM F2040 and EN 1077:2020 certifications confirm that every Revi helmet meets recognized international standards for snow-sports protection. Each test verifies impact absorption, retention strength, and shell integrity in conditions that reflect real on-mountain use.

Born in the Rockies. Built for Riders.

Revi was founded by riders who demanded better - who knew protection should perform as hard as the people wearing it. Every material, test, and detail was shaped by one belief: when comfort, fit, and protection work as one, confidence follows. And that’s where real progression begins.